Loading... Please wait...

Loading... Please wait...Save Money. Grow Your Own!

Fast Plain Box Shipping.

We ship to the US & Canada.

Posted on 30th Apr 2022

Metal labels are not that common on consumer products, but for certain industries, this is the go-to solution. For instance, if you are in the aerospace industry, food industry, or heavy machinery industry, you will be familiar with how all the machinery is marked with a metal label as opposed to a simple paper label or having the specifications printed on the equipment itself.

Metal labels offer security, clarity, reliability, and durability. In certain conditions, having a metal label is the only option. In fact, in a number of industries, it is a formal and legal requirement for machinery to be properly marked using a metal label. It’s important for equipment manufacturers to get the design and the construction of the metal label right so that they don’t face any problems from regulatory authorities and so that installing the label and using it is a stress-free process. Here are a few tips to help you get your metal label requirements right.

The first thing to assess is the asset itself. What kind of regulations does the labeling on the asset need to meet? What is the asset going to be used for? What environment is the label going to be used in? These questions will help you determine the kind of label that will be right for you. For instance, a lot of government agencies that buy equipment from private manufacturers require there to be a UID on the equipment. In some cases, the exact specifications of the UID are also mentioned and in other cases, the manufacturer is free to choose their own UID.

Similarly, if you are producing equipment to be used in the food industry then you will be required to use labels that are made of food-grade stainless steel. Regardless of how big they are or what kind of information they display, it is a standard in the food industry.

In the case of the food industry, the metal is clearly defined and that is what you will be using. In other situations you might be directed to only include certain kinds of information on the label and that the label must be metal. This still leaves you with quite a few options because you could make it out of brass, steel, iron, copper, or any other kind of metal. In this case, it helps to consider the purpose for which the equipment will be used. The team at Metal Marker Manufacturing recommends that you stick with a type of metal that exceeds your requirements, rather than one that exactly meets those needs. Especially if you are producing equipment that is likely to be in use for several years or decades, it can help to have that added durability and reliability. If your labels just meet the requirements, then as the metal weakens over time it could pose a serious risk. With a slightly stronger metal, you will know that even over several years, and even when the metal starts to weaken, it will still be performing at the required standard.

Equipment that is designed to be used in the industrial sector is most likely going to be exposed to high temperatures, abrasive surfaces, or even corrosive chemicals. For equipment manufacturers, it is critical that they select a material for the label which will be able to withstand these conditions. An incorrect choice of metal will not only cause the label to get damaged or wear out, but it will also lead to a health and safety risk.

Equipment is used in all kinds of situations where it is exposed to a wide variety of elements. For instance, electrical motors are one of the most widely used kinds of equipment in industries. They are part of every manufacturing process in some capacity. The metal labels on these devices are exposed to high temperatures, UV light, water, humidity, oil, grease, chemicals, and many other elements. The labels can be deformed, warped, rusted, or damaged in many ways. If you were to use a plastic label, it simply wouldn't last, but even when using a metal label you need to be very careful with the material you use.

It's also important for manufacturers to take into account the natural climate of the region where the equipment is going to be used. In regions where it is extremely cold, in coastal areas, or in regions where it is extremely hot, the equipment and the labels on the equipment face unique challenges.

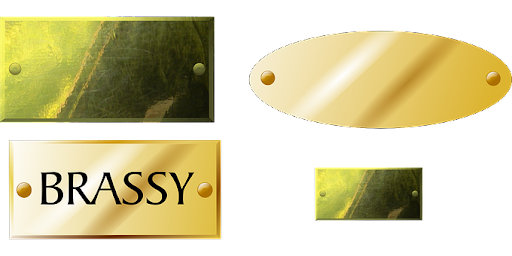

The label itself is composed of a few different layers depending on the kinds of specifications you have it made for. The top surface is designed to show the information, but the layer underneath, the substrate, is what provides the label its durability and longevity. The most common metals used for this layer are aluminum, brass, and stainless steel. For the longest time stainless steel has been seen as the most durable choice. It is commonly used in food, medical, chemical, or industrial applications.

Within stainless steel options, stainless 316 steel and 304 steel have been the most popular sub-types. Recently, aluminum options have also become more popular as newer versions of this steel are being developed and they are working just as well as stainless steel. Brass is a preferred option where electrical conductivity is a top priority or where the aim is to get a slightly more visually appealing label since the brass label can be customized in a number of ways. However, because it is a soft material it doesn’t do too well in harsh environments.

When constructing the labels for your equipment there are multiple kinds of metals that can be used for the different layers that the label comprises. However, your choice of metal type is only one of the considerations when manufacturing labels. You also have to look into whether this label is going to be secure on the equipment, how you want it printed, how it will integrate with the equipment, and whether you want to buy these as a fully-finished product or complete part of the process on your own. Working through all these considerations beforehand will make the entire process that much easier for you.